Go back in time with us to see our achievements over the years starting all the way back in 2003!

Chassis: A newly designed steel spaceframe incorporates anthropometric data for an improved driving position and enhanced component accessibility, particularly for the powertrain. Manufactured in-house, the updated chassis is ready for the 2025 event. Electrical: The proven SEVCON Gen8 inverter remains in use, with continuous improvements being made. Aerodynamics: NR16 marks the team’s first foray into functional aerodynamics, featuring a rear wing designed using Computational Fluid Dynamics (CFD) software. This ambitious project is guided by new supervisors and third-year engineers. Powertrain: The NR16 powertrain is a complete redesign from NR14. While the motor and differential are unchanged, the system now employs a lightweight chain drive inspired by MotoGP technology, with a custom 7071T6 aluminum rear sprocket. Revised motor and differential mounts reduce total mass by over 50% and rotational mass by 90%. Adjustable gearing ensures optimal performance for each event. Suspension: The car retains a double wishbone, pushrod-actuated bell crank setup, now featuring greater adjustability, anti-squat, and anti-dive geometry. These refinements improve aerodynamics, handling, and power delivery under acceleration and braking.

The NR14 features a mid-mounted EMRAX 228 electric motor driving the rear wheels through a DREXLER limited-slip differential via a carbon-reinforced belt drive. Custom-machined eccentric mounts ensure optimal tensioning, enhancing weight distribution and handling for maximum performance. Suspension: A double wishbone, independent pushrod-actuated bell crank suspension ensures consistent tyre contact for maximum grip and tunable performance. Electrical System: The EMRAX 228 is managed by a SEVCON Gen8 inverter and powered by a custom high-voltage Lithium-Ion battery. A bespoke Battery Management System (BMS) provides real-time data on temperature, voltage, and current, displayed on a steering wheel-mounted LCD for driver safety and optimal performance. Chassis: The in-house designed steel spaceframe offers a stiff, lightweight structure, providing a solid foundation for high-performance driving.

NRX was the first UK-built electric car to pass Formula Student scrutineering. Weighing in at 314kg it featured an aluminum honeycomb sandwich panel monocoque and was powered by an EMRAX 228 motor. With it, Newcastle Racing set the fastest UK electric vehicle sprint time of FSUK 2017.

Prior to NRX, this was the closest we had come to competing dynamically at Formula Student with an electric car. It passed all of electrical scrutineering, something we believe no other UK electric team had done at that time. However, NR9 was not allowed to compete as the brakes could not be locked without assistance from the regenerative braking system.

NR8 was the first electric NR car. It was developed over an extended period of time, due to the steep learning curve involved. Not only was NR8 our first EV, it was also our first venture into a sandwich panel monocoque chassis. Powered by a 3-phase AC synchronous brushless motor, NR8 was a valiant first attempt. However, along with every other EV produced by a UK team that year, it failed to pass scrutineering and compete in the dynamic events.

NR7 was destined to enter the FSUK 2010 event, but despite being fully assembled, it unfortunately never made it to the event. You’ll have to take our word for it as we have no photos, due to it being disassembled shortly after completion for research purposes. It was powered by a Honda CBR-RR600 engine, featured a bell-crank suspension system and 10 inch wheel rims.

One of our most successful FS cars ever, NR6 reused the rear of NR5, with a new sandwich panel monocoque front. This was employed with the aim of increasing stiffness while reducing mass. Both steering and suspension were overhauled to improve handling. Silage wrap proved an effective method of waterproofing against the torrential rain experienced at the event.

A development of NR4, it featured upgrades including a carbon fibre intake plenum. Unfortunately as is often the case with FS cars, a small niggle stopped it achieving greatness, this time being a tricky hand operated clutch.

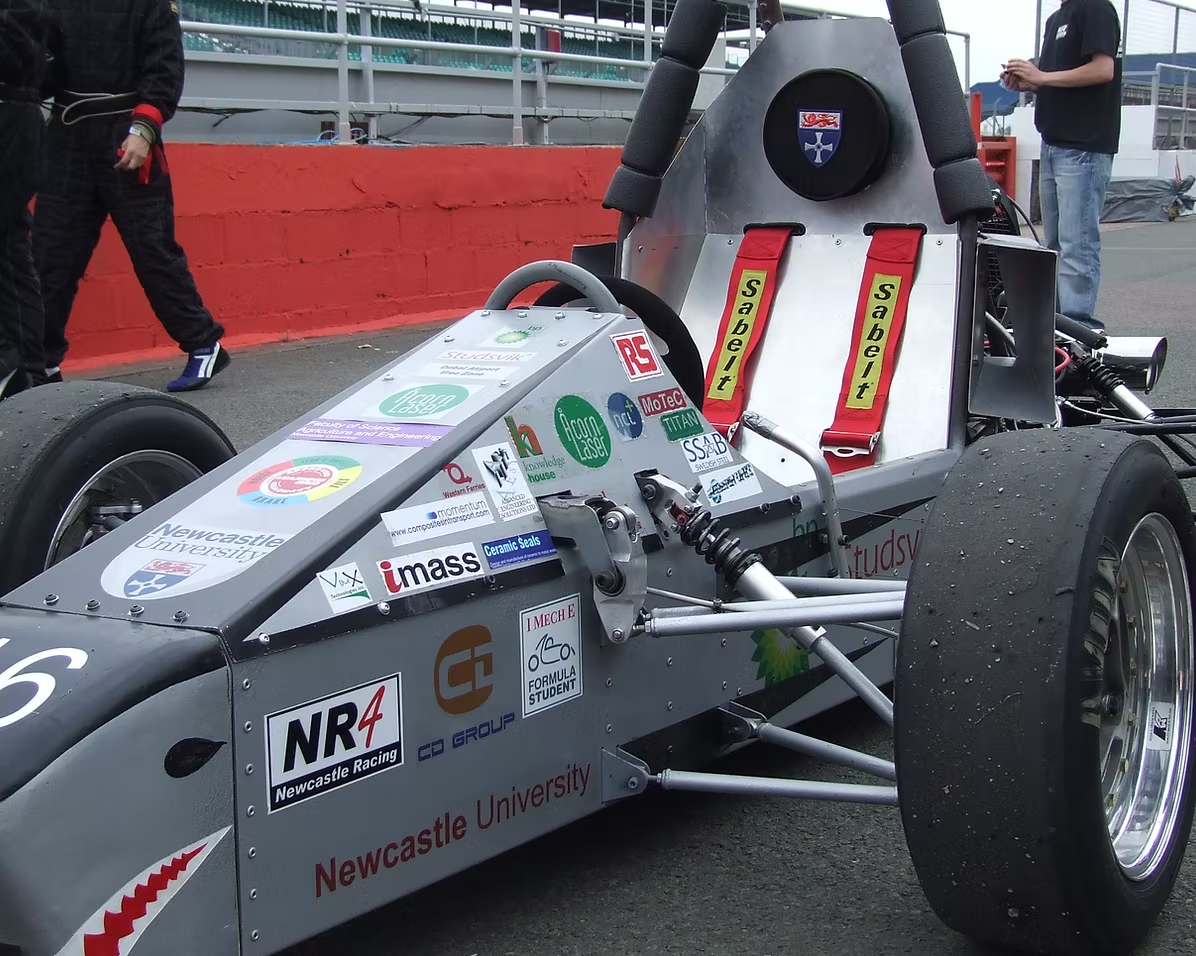

NR4 chassis was constructed from 3mm thick aluminium sheet and powered by an air-cooled 600cc Ducati Monster Engine. This gave it a power to weight ratio higher than a contemporary Aston Martin DB9, and a top speed in excess of 100mph. NR4 made it to the endurance event of the FSUK 2007, before the clutch gave in, a not uncommon occurrence with ICE cars of this performance.

2006 was the year when the word “JUST” echoed through the bay. We “JUST” have to finish a car. We “JUST” have to manufacture a car. We “JUST” have to design a car. As such, it was a no show, NR2 was re-entered as a “200” (second entry) car where it put in a commendable performance.

NR2 featured a Honda motorbike engine, nestled in a mild steel space frame chassis. Whilst reliable, it lacked handling finesse. As with every successful race team, this car was used as a base from which to improve on, and was therefore a key step in the journey to where we are now.

NR1 featured a mild steel tubular spaceframe, TIG welded together. It made it all the way to the endurance event of FSUK 2004, where it had to take early retirement due to dirt in the fuel system.